This question is one of the most often asked of us. There seems to be a baffling array of things to consider but these can easily be worked through. Let us look at the steps along the way of to choosing the right size pump for a typical bore pump installation for “stock and domestic”.

1. How Much Water

The first step is really to decide how much water you need to pump. This will depend upon your circumstance (you can find a guide here) but lets say you wish to pump 20,000 litre per day for average weather conditions to water stock by pumping from a bore to a header tank that then flows out to troughs in the paddocks.

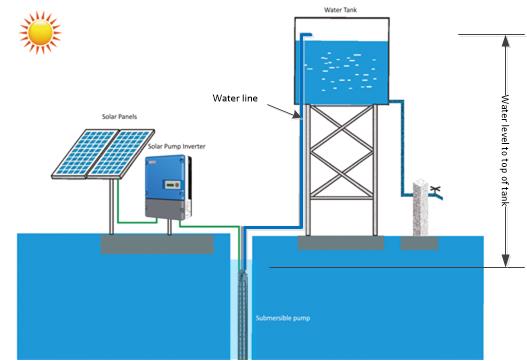

Let us assume that this is a new bore and that the pump is going to be powered by a standalone off-grid solar pumping inverter. The pump is going to operate only during daylight hours and for the average time of year we can count on 5 hours of operation per day.

2. Site Data

The second step is to collect some site data of how deep is the bore, what is the water level in the bore, what height is the tank inlet so the height difference from water to top of tank can be estimated. You will also need an estimate of the length of the water line from the pump to the top of tank.

Height difference. For our case study here, let us say that the height difference between the top of water and the outlet into the tank is 73m. (Height differences are easily measured using phone apps such as GPS Essentials). When pumping, the water level in the bore will be drawn down so add 2m to the height difference to compensate. For our study the height difference we will assume is 75m.

Water line. The length of the water line, how many valves, elbows and other restrictions, along with the size of pipe and what it is made from all feed in to what pressure loss the pump will have to overcome. All sounds complicated but we can make some appropriate assumptions to ease the way.

- Pump Volume. The pump volume is simply the daily demand divided by the operational hours per day. In our case 20,000 l ÷ 5 hrs = 4000l/hr or 4m^3/hr (approximately 880 gallons per hour).

- Pipe Size. Use the Head Loss Calculator to find a combination of flow velocity and head loss that you are comfortable with.

Head loss calculator

| Static Head | ||

| Flow Rate | ||

| Pipe Diameter | ||

| Pipe Length | ||

| Pipe Material | ||

Head Loss |

|

|

Total Dynamic Head |

|

Contact Us